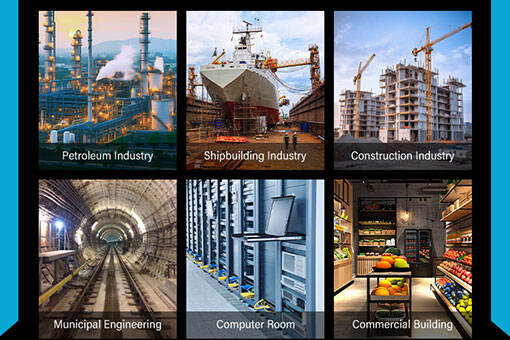

Common Application Scenarios

Power Substations: Supports high-voltage cables, ensuring stable power transmission. Many power substations have chosen SFDQ cable trays for their reliable quality.

Industrial Plants: Manages power and control cables, reducing wear and tear in harsh factory conditions. Our cable trays are widely used in various industrial plants, with excellent adaptability.

Commercial/Residential Buildings: Organizes power, telecom, and security cables, improving indoor aesthetics. SFDQ cable trays have a sleek appearance, matching the interior design of modern buildings.

Data Centers & 5G Base Stations: Isolates power and data cables to minimize electromagnetic interference, ensuring smooth signal transmission. We provide customized cable tray solutions for data centers and 5G base stations, meeting their specific needs.

How to Choose the Right Cable Tray

Assess the Environment: Pick materials based on corrosion levels (e.g., FRP for chemicals, stainless steel for coasts). SFDQ factory’s professional team can provide material selection suggestions according to customers' use environments.

Calculate Load: Determine the number and weight of cables to select a tray with sufficient load-bearing capacity. We can calculate the required load-bearing capacity for customers and recommend suitable cable tray models.

Match Cable Types: Use trough-type for sensitive cables and ladder-type for heavy power cables. Our team will match the most suitable cable tray type according to the type of cables used by customers.

Consider Installation Space: Opt for mesh or tray-type in tight areas for easier installation. SFDQ factory can provide customized cable tray sizes according to the installation space provided by customers.

Shenyang Sanfeng Electric Co., Ltd. is an enterprise specializing in the design, research and development, manufacturing and sales of cable tray. The company was established in 1993 with more than 30 years of industry experiences. Our products have been exported to over 40 countries and regions, including Southeast Asia, Europe, and Africa, winning trust from 500+ long-term corporate clients. We have successfully participated in multiple key projects, such as municipal infrastructure constructions and industrial park expansions, proving our product reliability in practical applications. Our R&D team consists of 15+ senior engineers, who continuously optimize product structures to meet the evolving needs of industries like power, construction, and data centers. Equipped with 5 advanced automated production lines, we achieve a monthly output of 20,000 sets of cable trays, ensuring on-time delivery even for large-volume orders.

Case 1: A Large - Scale Automotive Manufacturing Plant

A well - known automotive manufacturing plant was facing significant challenges in its power and data management systems. The existing cable management system was outdated, with cables running haphazardly, leading to frequent disruptions in power supply and data communication. This was causing production delays, costing the company a substantial amount of money in lost productivity.

After conducting a thorough assessment, the plant decided to install our factory - produced cable trays. The installation team chose a combination of ladder - type and slot - type cable trays. The ladder - type cable trays were used for the high - power electrical cables that supplied power to the large - scale manufacturing equipment, such as robotic arms and conveyor belts. Their excellent heat - dissipation properties ensured that the high - power cables did not overheat during continuous operation.

The slot - type cable trays were installed for the data - communication cables that connected the various sensors, PLCs, and computers in the factory. These cable trays effectively shielded the data cables from electromagnetic interference, ensuring stable and high - speed data transmission.

The results were remarkable. After the installation of our cable trays, the frequency of power - supply disruptions decreased by 80%, and data - communication failures were almost eliminated. The production line was able to operate smoothly for longer periods, leading to a 15% increase in daily production output. The plant also saved on maintenance costs as the organized cable layout made it easier to identify and fix any issues.

Cable trays are a key investment in electrical system efficiency and safety, and SFDQ’s diverse range caters to every project need. As a professional SFDQ cable tray factory, we master the full production chain for all structure and material types, ensuring each product meets global standards. Whether you need trays for outdoor power projects, industrial workshops, or data centers, SFDQ can provide customized solutions to optimize your cable management. Choose SFDQ, and rely on quality that lasts for decades.

Let’s Build Your Next Production Hub

If you’re looking to expand capacity, upgrade facilities, or integrate efficient systems for heavy-duty manufacturing, SFDQ is your trusted partner. We bring the same expertise that powered Futian Daimler’s success to every project.

Copyright © 2026 Shenyang Sanfeng Electric Co., Ltd. Beijing All rights reserved. — Privacy Policy